How to Replace the Capacitors in a 1G ECU

![[NOTE!]](/g/note!.gif) This document is

provided as a guide for an experienced repair technician. While this repair is

not the most difficult one to perform, there are many ways in which the ECU can

be damaged. Any experienced electronic hobbyist should be able to do this

repair. We believe this document to be accurate. However,

TechnoMotive is not responsible for any

errors, nor for any use or misuse of this document.

This document is

provided as a guide for an experienced repair technician. While this repair is

not the most difficult one to perform, there are many ways in which the ECU can

be damaged. Any experienced electronic hobbyist should be able to do this

repair. We believe this document to be accurate. However,

TechnoMotive is not responsible for any

errors, nor for any use or misuse of this document.

What is an Electrolytic Capacitor?

A capacitor is generally

used in an electronic circuit to filter out unwanted signals. The electrolytic

capacitors in the DSM ECU are used to filter the power supply. An automobile is

an extremely hostile place for electronics. The output of the alternator isn't

all that pretty to begin with. Couple that with the spark plug high voltage

firing, the radiator fans, the interior fan, turn signals going on and off...

the +12VDC main power line gets a lot of crud on it.

A capacitor is generally

used in an electronic circuit to filter out unwanted signals. The electrolytic

capacitors in the DSM ECU are used to filter the power supply. An automobile is

an extremely hostile place for electronics. The output of the alternator isn't

all that pretty to begin with. Couple that with the spark plug high voltage

firing, the radiator fans, the interior fan, turn signals going on and off...

the +12VDC main power line gets a lot of crud on it.

Which capacitor to choose? There are a lot of different types

out there - some large, some small, some really accurate, some "cleaner"

for low noise applications, etc. For power supply filtering, electrolytics are

almost always used. Power supplies generally require a large capacitor to

absorb spikes and dips. You can't afford not to have a steady power supply line

inside of a computer - the microcontroller might act erratically or reboot.

Electrolytics are chosen because they provide a lot of filtering for their small

size. They are also very cheap.

The Problem

Electrolytic capacitors do have a downside, though. They tend

to leak with age when exposed to heat and many power cycles. The electrolyte

that leaks out is very harmful to PC boards. It can actually eat the copper

traces, eventually making a short on the board. When that happens, the ECU will

either stop working altogether or act very erratically. As the capacitor leaks,

it will also lose its filtering properties, allowing possibly harmful spikes

into the ECU.

Signs of Impending Doom

Luckily, there are usually some warning signs that your ECU is on its way

out.

- A rapid clicking or chattering from under the dash. Usually accompanied

with the engine stalling or losing power during the noise. This is the

microcontroller going into reset over and over and over again due to a bad power

supply. Every time it resets, it will turn the fuel pump relay on and off.

This could also be a bad fuel pump relay, but not usually.

- An usual smell that seems to come from the center console. Especially if

it smells like rotten seafood. Consider that it could also be your heater fan

motor, unless accompanied with a power loss or stalling.

- Your car is older than seven years and sees a lot of extreme temperature

transitions.

If you experience either of the first two problems above, act on them as

soon as possible. Even though your car may still be drivable, the longer you

let the problem go the more likely you will end up with a hole in your ECU's PC

board or with several blown components on the board. Then you will have to dig

a unit up in the junkyard or buy a new one from Mitsubishi for $1100.

The Solution

Purchase the Replacement

Capacitors. Unfortunately, the particular capacitors you need can't be

found at Radio Shack. They can be found at a

Digi-Key, however.

Purchase the Replacement

Capacitors. Unfortunately, the particular capacitors you need can't be

found at Radio Shack. They can be found at a

Digi-Key, however.

- 47µF @ 50V (Digi-Key# P5275-ND)

- 22µF @ 50V (Digi-Key# P5273-ND)

- 100µF @ 16V (Digi-Key# P5231-ND)

For your convenience, you

may press the next three buttons in sequence to order these capacitors from

Digi-Key. When you get to the form, fill in the quantity (probably 1) and then

press "Add to Order". Then hit your browser's BACK

button to return to this screen. After the third button, hit "Submit

Order" at the bottom of the Digi-Key screen to place your order. If

you make any mistakes, hit "Delete All Items" and start again.

The cost of the capacitors is about 81¢, but there will be about $10 in

shipping in handling fees.

By

the way, in general, you can "up" either the voltage rating or the

capacitance of the capacitor in a power supply application if you wish. For

example, instead of 50V capacitors, you could use 63V capacitors. You just have

to make sure that the body-style of the capacitor is "radial" (both

leads coming out of the botttom, as opposed to "axial") and that it

will fit.

Gather Supplies. Although the

instructions below are written for using copper solder braid and a solder

sucker, we highly recommend using a professional desoldering station with its

own air supply. A solder sucker and solder braid will do the job, but are much

slower and not as accurate at the real thing. Make sure you have a good

soldering iron with a large tip. You are also going to need some solder.

Gather Supplies. Although the

instructions below are written for using copper solder braid and a solder

sucker, we highly recommend using a professional desoldering station with its

own air supply. A solder sucker and solder braid will do the job, but are much

slower and not as accurate at the real thing. Make sure you have a good

soldering iron with a large tip. You are also going to need some solder.- Remove the ECU. The first thing you will have to do is take the

ECU out of the center console. We have a HOW-TO

available with pictures for both the 89-94

and 95+ DSMs.

- Remove the PC board from the case. Now would be a good time to put

a grounding strap on your wrist, if you have one. Take the four screws out of

the side of the case. Keep in mind that they might be incredibly tight. At

least one usually is. Consider using a flat-blade screwdriver very carefully on

the tough ones to allow for better torque. There are also four screws in the

corners of the PC board itself. The same rule applies to those screws as you

try to remove them.

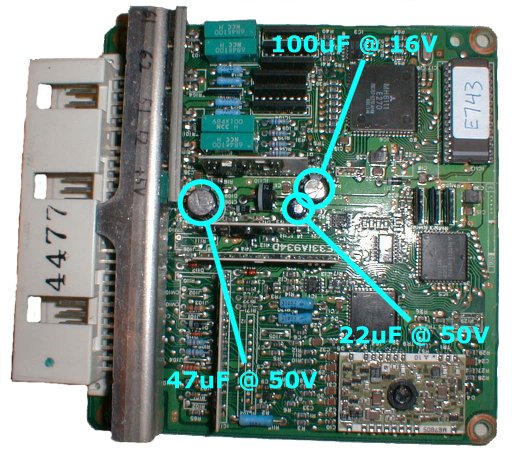

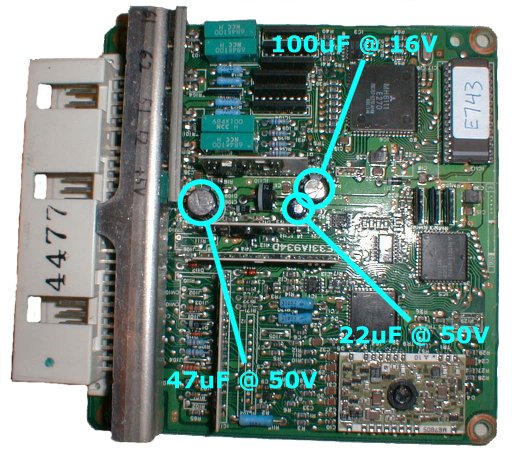

Figure 1

The

Three Capacitors

- Locate the Capacitors. Figure 1 shows the positions of the

capacitors and their values. You might want to inspect them for any sign of a

leak or maybe a smoke trace if you've had a problem.

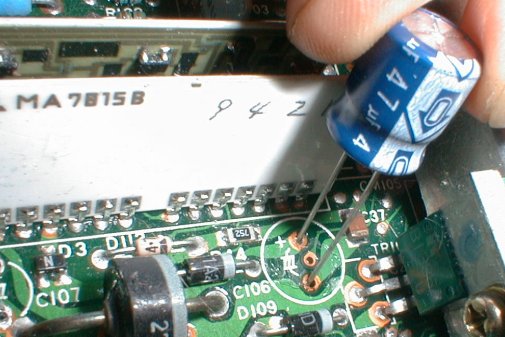

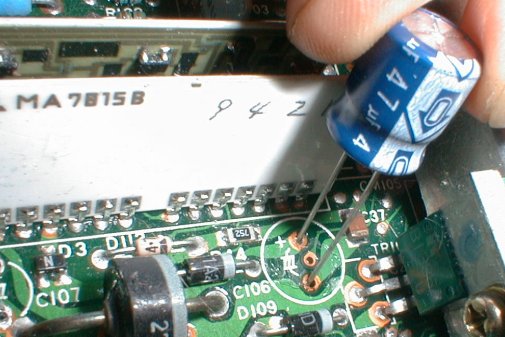

Figure 2

Adding

Solder

- Add Solder to the Capacitors. Why do we want to add solder

when we will just be sucking it away later? When the boards are wave soldered

at the production factory, solder will attach to the capacitor leads on both

the top side and bottom side of the thru-hole copper pad. It is possible that

there is little or no solder in the hole between the top surface and the bottom

surface. By adding solder back in, we assure ourselves there will be enough

solder to conduct heat from the bottom of the board to the top of the board and

melt the solder on the top surface of the pad. That will make sucking the

solder out all that much easier and ensure that we won't be ripping the top off

the pad when we take the capacitor out. Figure 2 shows solder being

added to the 47µF capacitor. It also shows the position of all of the

capacitor leads relative to the huge diode posts, which are unmistakably huge.

Note that all of the capacitor legs are bent outwards while all resistor and

diode leads are bent inwards.

Figure 3

Bending

Leads

- Bend the Capacitor Leads. Now would be a good time to straighten

out all of the capacitor leads. Figure 3 shows this being done with a

tweezers while heat is applied with a soldering iron. This will make it easier

to both solder suck and remove the capacitors later.

Figure 4

Sucking

the Solder

- Suck the Solder. Figure 4 shows the relatively mundane

task of sucking out the solder. Make certain that the solder is nice and hot

and is flowing well before you fire the trigger of the sucker. If you do it

right, the solder will be sucked off the top layer of the board as well.

Figure 5

Cleaning

the Pads

- Clean the Pads. The hand-held manual solder sucker rarely gets all

of the solder. Most of the time, you have to clean up after it. Figure 5

shows copper solder braid being used to sop up all of the residual solder to

ensure a clean pull of the capacitor.

Figure 6

Popping

the Capacitor

- Pry out the Capacitors. Using a tweezers or small screwdriver,

carefully pry out the capacitors. If you encounter some resistance and it

doesn't feel "right", you might want to go back and reclean the pads

or go as far as adding back more solder and beginning the process again.

Remember that you don't want to "pop" one of the thru-hole pads, or

you will be doing some repair. Figure 6 shows the 47µF capacitor

getting removed.

Figure 7

Board

without Capacitors

- A Look at the Naked Board. Now that the capacitors are off, you

should give them a good sniff. If any of them smell at all like rotten seafood,

they are leaking. Be sure to pay attention to the area of the board underneath

a leaking capacitor. For example, the ECU in these pictures had the faintest

odor of rotten seafood from the 47µF capacitor. In Figure 7,

notice that the bottom hole pad shows some darkness around the lower pad. It is

the beginning of the oxidation of the copper pad. This ECU was caught just in

time. Another thing that should be noticed in Figure 7 is the marked

polarity of the hole pads. Inserting a capacitor "backwards" can lead

to an explosion.

Figure 8

Capacitor

Polarity

- Install the Capacitors. It is EXTREMELY IMPORTANT that you

install the capacitors with the correct polarity. If you do not, the capacitors

might explode, doing who knows what damage to the board. In Figure 8,

on the capacitor, you can clearly see the negative sign inside of the arrow

pointing to the lead that is negative. Note that the hole on the ECU PC board

which the negative lead is going into is NOT marked with a "plus

sign". Only the positive hole is marked on the ECU. Be sure to put the

negative lead in the opposite hole. After you push the capacitor all the way

down, take the leads on the bottom and bend them outward as they were from the

factory. This will hold them in place for soldering.

Figure 9

Soldered

Capacitors

- Solder the Capacitors. Downhill from here on out. Solder each of

the capacitors as in Figure 9. Be sure to trim off the leads so there

isn't a short.

Figure 10

Removing

Solder Blobs

- Cleanup. Almost done! Check out the soldering job using a

magnifying glass. Often, the solder will splatter a bit when using the solder

sucker and solder braid. Use a fine tweezers as in Figure 10 to remove

each small piece of solder or metal that represents a possible short. Then

screw the PC board down into the bottom of the ECU case, put the cover on the

ECU case, and you are ready to go!

©1998 TechnoMotive

August 11th,

1998

![[NOTE!]](/g/note!.gif) This document is

provided as a guide for an experienced repair technician. While this repair is

not the most difficult one to perform, there are many ways in which the ECU can

be damaged. Any experienced electronic hobbyist should be able to do this

repair. We believe this document to be accurate. However,

TechnoMotive is not responsible for any

errors, nor for any use or misuse of this document.

This document is

provided as a guide for an experienced repair technician. While this repair is

not the most difficult one to perform, there are many ways in which the ECU can

be damaged. Any experienced electronic hobbyist should be able to do this

repair. We believe this document to be accurate. However,

TechnoMotive is not responsible for any

errors, nor for any use or misuse of this document. A capacitor is generally

used in an electronic circuit to filter out unwanted signals. The electrolytic

capacitors in the DSM ECU are used to filter the power supply. An automobile is

an extremely hostile place for electronics. The output of the alternator isn't

all that pretty to begin with. Couple that with the spark plug high voltage

firing, the radiator fans, the interior fan, turn signals going on and off...

the +12VDC main power line gets a lot of crud on it.

A capacitor is generally

used in an electronic circuit to filter out unwanted signals. The electrolytic

capacitors in the DSM ECU are used to filter the power supply. An automobile is

an extremely hostile place for electronics. The output of the alternator isn't

all that pretty to begin with. Couple that with the spark plug high voltage

firing, the radiator fans, the interior fan, turn signals going on and off...

the +12VDC main power line gets a lot of crud on it. Purchase the Replacement

Capacitors. Unfortunately, the particular capacitors you need can't be

found at Radio Shack. They can be found at a

Purchase the Replacement

Capacitors. Unfortunately, the particular capacitors you need can't be

found at Radio Shack. They can be found at a

Gather Supplies. Although the

instructions below are written for using copper solder braid and a solder

sucker, we highly recommend using a professional desoldering station with its

own air supply. A solder sucker and solder braid will do the job, but are much

slower and not as accurate at the real thing. Make sure you have a good

soldering iron with a large tip. You are also going to need some solder.

Gather Supplies. Although the

instructions below are written for using copper solder braid and a solder

sucker, we highly recommend using a professional desoldering station with its

own air supply. A solder sucker and solder braid will do the job, but are much

slower and not as accurate at the real thing. Make sure you have a good

soldering iron with a large tip. You are also going to need some solder.